Ferrari sticky buttons

It’s puzzled enthusiasts, collectors, and retailer alike…how does something soft to the touch, turn into a gooey, shiny, and messy problem?

It seems there’s not one definitive answer. However, there are a few common denominators:

Using incorrect products to clean and condition the soft-touch surfaces

Exposure to sun

Exposure to heat

Buttons touches the most will wear down with body oils

External temperature and humidity fluctuations

Replacing with new parts from Ferrari will simply leads to another round of replacing in a few years

A viable and more permanent solution is to refinish the buttons and pieces completely. This process is extremely labor intensive and only a few companies in the world have the technology to execute to a high degree

The process here at GP is truly a labor of love and years of experience dedicated to Ferrari specialization

Here’s the journey outlined:

Inventory of what parts needing refinishing are detailed to client and scope is defined

Disassembly begins. Unique FYI about Ferrari…almost every part is screwed in, not much is a pull/push type.

In this project, Ferrari 458 Speciale, the entire upper dash required removal just to gain access to various hidden screws to remove parts such as vents, climate control, infotainment, etc.

Tremendous care and cataloging of each screw with precise location was done

Parts are carefully wrapped for transport

Each part is meticulously clean and prepped for the new specialized coating that mimics the look and feel of original buttons, but will never get sticky again

Parts are then coated and laser etched to manufacture specifications revealing identical font and labels

Each part is then inspected by refinisher and safely shipped back to GP

Once parts arrive, they are further inspected for quality control, and if necessary, they will be refinished if they don’t pass GP quality control

Each part is then prepped, surrounding areas cleaned, and part reinstalled methodically in reverse manner of removal

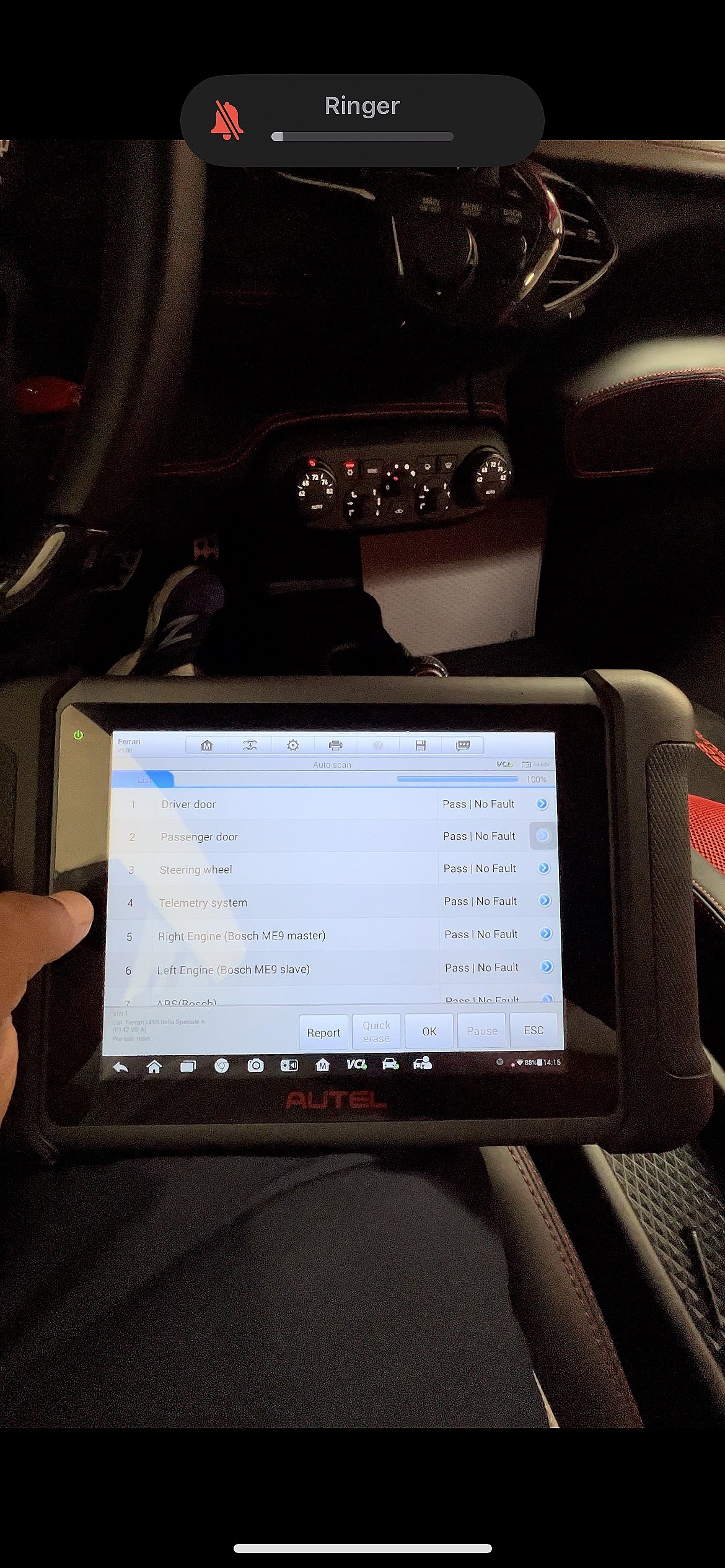

All electronic parts are checked for full function

All screws, spacers, nuts, etc. hand tightened

Final inspection

Vehicle is connected to diagnostic tool and any error codes are reset

This may seem like a lot of effort, but it’s the correct way to make sure the job is done right, and the results stand the test of time for future generations